Today, we have moved well beyond the time when decisions were made at the top of an organisation and then passed ‘down the line’ to ground floor operatives. In modern organisations, important decisions need to be made by individual employees who are directly involved in production processes and interact face-to-face with customers. The term associated with this change is ‘empowerment.’ Many modern employees are ‘empowered’ to think things through for themselves and take the appropriate actions. This involves a higher level of ‘trust’ in employees – that they will make the right decisions. However, to ensure that employees are able to take on the new responsibilities associated with empowerment, it is essential that they are given the necessary training for their enhanced duties. This case study focuses on methods used by a leading UK company to move decision making ‘down the line.’ It examines how British Steel Strip Products, Integrated Works at Llanwern, engaged in a training programme based on empowerment, resulting in the company winning the National Training Award in 1995.

The Llanwern Works

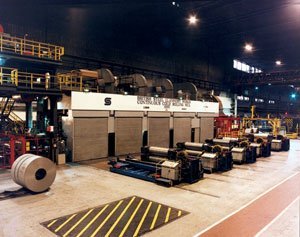

Llanwern Works is a fully integrated steelmaking plant and a principal unit within British Steel’s Strip Products business. It was constructed on a greenfield site near Newport, Gwent. The plant has a liquid steel capacity of three million tonnes per year, which is processed into hot and cold rolled strip steel (including zinc alloy coated strip) to precise tolerances in both coil and sheet form.

Recently, organisational restructuring at Llanwern has fully combined the Works with its sister plant, Port Talbot, to become a responsive single operating unit (Integrated Works), employing 7,500 people and capable of producing just over six million tonnes of steel per year.

Business environment

Llanwern’s traditional products are supplied to blue chip customers in the automotive, consumer durables and construction industries. All operational activities within the plant are driven by the demanding standards of product quality and service required by these customers. This is achieved within an established Total Quality Performance (TQP) culture. TQP refers to the approach used by British Steel in order to improve its performance on a systematic and continuous basis. It allows the entire organisation to focus on the needs of the customer.

Nowadays, there is intense competition in the market place – world-wide, there is a considerable overcapacity for steel strip products i.e. too many producers making more products than the market currently demands. In order to survive and prosper, it is essential to beat the competition. Senior managers at British Steel recognised the best way forward was to improve manufacturing performance and increase output per head. This could only be achieved by having a highly skilled, fully flexible and committed workforce.

Staying ahead of the field

Due to intense international competition, British Steel Strip Products recognised the urgent need for a rigorous training programme, geared towards improving manufacturing performance, productivity and creating a skilled, flexible and committed staff. The Works adopted an all-embracing approach and training was extended across the breadth of the Cold Mill workforce ’from admiral to cabin boy.’

Improved performance

In 1993, the quality of cold mill steel was causing some commercial concerns. Significant increases in surface quality required for steel used in car body panels came from the automotive sector – mainly from Japanese car companies with production units in the UK. At the same time, the Works’ TQP philosophy was taking root and senior management was anxious that the principle of TQP should be reflected within a more participative style of management. Studies also revealed standards had fallen below those of some of British Steel’s main competitors. Many employees believed that the only way to improve quality was to lower the volume of production. They did not realise that both quality and output could be raised simultaneously.

Managers chose to overcome these deficiencies by drastically improving the product quality performance of the mill through the increased personal competence, attitude and involvement of the workforce. Management set out to change attitudes and improve employees’ skills by focusing on three overriding objectives:

- To ensure product, process strategy and performance was totally focused on meeting the customers’ definition of quality

- To achieve a transformation in the cold mill workforce’s (including management) perception of quality effort on volume

- To unleash the full potential of production operatives by providing the necessary culture and skills for a more participative style of decision making within the operation.

Key objectives

In creating the training programme, two objectives had to be met:

- To increase operators’ product/process knowledge, problem-solving and decision making skills. Operative competency was traditionally based on technical skills. It did not include the problem solving/decision making skills and product/process knowledge which would reduce time spent by operatives referring to management for help.

- To improve management style and expertise, thus making the programme effective. The new empowerment based approach could only be effective if it was fully understood and supported by all managers.

The Cold Mills Development Programme (CMDP) was designed and launched. Llanwern selected nine Lead Unit Trainers on the basis of job knowledge, communication skills, self confidence/ assertiveness, perseverance and a sense of humour. There were a number of steps involved in training design.

Step 1: Developing a Cold Mill operator profile:

- Analysis of job demands. This consisted of a questioning approach – studying operator jobs and interviewing shift managers, supervisors and senior operators. It enabled unit trainers to gauge key demands, competencies and behaviours which, although not directly trained for in the past, nevertheless differentiated very good operators from those working to a demonstrably lower standard.

- Identification of competencies using psychometric assessment. After job analysis, a further study was carried out on two distinct groups of current operators – one of perceived high level performers and one of lower performers. This provided an overview of the typical skills, abilities, behaviour attitudes and personality characteristics which separated the high performers from the under performers. The analysis generated an ‘ideal operator profile,’ allowing management to focus on the characteristics of an ‘ideal’ employee.

The aim was to encourage existing employees to recognise the ‘right’ characteristics, as well as using the profile for recruiting new employees. The profiles concentrated on job specifications (objectives, duties and responsibilities, job skills requirements) and personal specifications (physical characteristics, social factors, abilities and personal qualities). In general terms, more successful operators had developed an understanding and familiarity with customer specification, the product/process and end-use and were more sociable, stable and intellectually effective.

Step 2 – Competence matrix development

The nine Lead trainers were introduced to the programme during a three day workshop, which enabled them to write comprehensive training manuals. Unit trainers then produced competency matrices (detailed outlines of the competencies individual employees would need) for each production unit within the department, based on the traditional method of assessing newly identified skills to pre-defined standards. The required level of job skill and knowledge was indicated for each competence. Manuals were rigorously checked, amended and finally approved by management, to ensure that training design was appropriate to the changes that were being introduced.

Step 3 – Supportive management development skills programme

The next important stage involved training the managers to support the new initiatives. Managers needed to develop:

- The managerial skills to support the benefits of shopfloor training; team building, delegation and coordination, setting objectives and evaluating performance

- An understanding of the complementary relationship between training for personal empowerment and TQP/team building

- A culture (i.e. a way of doing things in the organisation) in which the central importance of customer/commercial considerations was of overriding importance

- State-of-the-art knowledge of current cold mill technology.

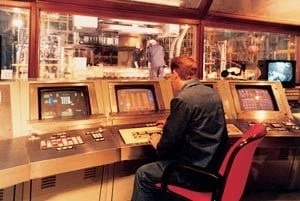

Having established the nature, purpose and procedures for the delivery of the training, it was then possible to implement the training programme. Training manuals were used to assess all operators individually, to identify competency shortfalls and consequent training needs. Managers and supervisors followed a series of modules to develop their understanding of production management, supply chain management, process and product technology. They also visited major customers and took part in competitive edge workshops.

Training

The programme was introduced to the Llanwern Cold Mill in August 1993. Briefing sessions were used to present the concept, objectives and practical aspects of operator training to all managers and supervisors. Senior departmental management ensured that the importance of the training programme was appreciated by all members of the department and given the appropriate priority. Manuals were used to assess all operators within the units concerned and, in total, 342 operators were assessed between August and October 1993.

Following assessment, unit trainers agreed a priority training programme with management and detailed training started in October 1993. Junior operators were trained for promotion, releasing senior operators for extensive high level training. Competence training was carried out on an individual basis with classroom training prior to on-the-job training. A series of detailed tests was used to check whether the required standards had been met. All 105 managers/supervisors were fully briefed on organisational objectives prior to the start of the formal training. Training was then delivered in two distinct parts:

Part 1

This consisted of a series of lectures by steel industry experts at the company’s residential management college, Ashorne Hill. Five modules were covered over a 12 month period:

- Process management module – developed an understanding of the key elements of cold mill production management and its commercial importance. World best performance was also reviewed.

- Cold Mills technical module – examined, in-depth, cold mill’s technology, process and products.

- Supply chain management – logistics, partnerships and alliances (internal and external) were reviewed.

- Nissan visits – two day visits to Nissan (Sunderland) to study the perceptions and concerns of a major customer.

- Competitive edge workshop – addressed key concerns such as low yield, cost control and preparing performance improvement plans (following customer visits).

Part 2

Individual assessments carried out by senior works management and based on British Steel’s ‘Core Management Competencies’ and ‘Production Training Standards’ highlighted development needs for individual managers to be tackled through personal action plans.

Innovative and more effective alternatives to traditional course based training were sought; individual and team projects, foreign visits focusing on set topics and European steel plant exchanges with the results presented by individuals to senior plant management. In all cases, managers’ performance continues to be appraised formally on an annual basis with appropriate actions developed as required.

The results

The results of the training programme at Llanwern justified the importance attached by management to this initiative. Managers have shown an improved management profile, self-esteem and effectiveness, trainers are better motivated and feel that they ’own’ the design and delivery of the programme and operators have greater problem-solving skills, confidence and motivation.

Fantastic savings resulted. Sheet rejections were reduced from 40 tonnes in 1992 to 10 tonnes in 1995. Line availability improved from 66.5% in 1992/93 to 77.9% in 1994/95. In 1994/95, there was an overall yield saving of £2.4 million. The Continuous Rolling Mill achieved an outstanding record of 31,475 tonnes per week in April 1995 compared to 17,981 in 1992. The value of training cannot be demonstrated better!

The British Steel case study provides an object lesson for modern organisations faced with a competitive business environment. In order to be the best, you have to beat the best. This involves leading organisations setting themselves standards to beat their previous best. Today, it is essential that all members of an organisation realise their potential, both for their own personal fulfilment and also to enable the organisation they work for to function efficiently. British Steel recognised the need to trust its employees, allowing them to make important decisions related to their own specialities and work competencies. However, in order to help employees take on this trust and responsibility, they needed the skills and expertise to become better decision-makers. To complement these changes, it was also necessary to change the attitude and approach of management so that ‘new managers’ would become facilitators of the empowerment process. Managers also needed detailed training to adopt these new styles of management. A key part of the process was allowing experienced trainers to take ownership of and to develop the new training course themselves – i.e. empowering the trainers. The process has been a resounding success.